How can your Heat Transfer Fluid benefit from Gopani's HTF Filtration System?

All Thermic fluids (HTF) are organic compounds consisting of Biphenyl Compounds with added Anti-Oxidants. Ignoring the health of your heat transfer fluids often leads to quality deterioration, and will have an impeding effect on the entire process. Knowing what causes the quality of these fluids to deteriorate is your first step to resist these attacks and optimize the efficiency of these fluids. Following are various causes of quality deterioration and its effect on the quality of HTF and hence on the entire process, in the table below.

| 1. | Ingress of air and oxidation |

|

|

| 2. | Lower velocity than minimum recommended velocity |

| |

| 3. | Pick of iron particles from pipe lines and vessels contact surfaces.( Particularly when charging HTF for the new System |

|

|

| 4. | Increase in TAN No |

|

|

These causes and the resulting deterioration of quality is often overlooked at the onset and only comes to notice when irreversible damage is done. This happens mainly because the Heat Transfer Fluid is perceived merely as a utility item and the operating crew focuses only on the production process, a primary objective in any industry.

Heat transfer fluid is a highly expensive raw material. It is important to focus on quality degradation prevention, therefore ensure a longer life and improved processes. One of the most important factor in maintaining its quality is to ensure that it is free from any type of contamination. In this scenario, a smart filtration system will do the job.

A Smart Remedial Action:

Filtering heat transfer fluids will do two things for you,

- Increase the service life of the HTF and

- Reduce the frequency and cost of maintenance

Heat transfer fluids are contaminated by polymers, iron and carbon particles. These contaminants can be removed using side stream filtration in SITU. The side Stream flow rate can be 2%-3% of total flow.

Gopani Products Systems has developed a full system with filter, valves, pump and PI. The system is Skid Mounted. The Inlet and outlet piping to system is buyer’s scope. The GA arrangement for this system is as below:

This filtration system is offered at short delivery period, and can be easily hooked into your existing heat transfer fluid circulation loop. The module can be hooked up to the main loop of your HTF system.

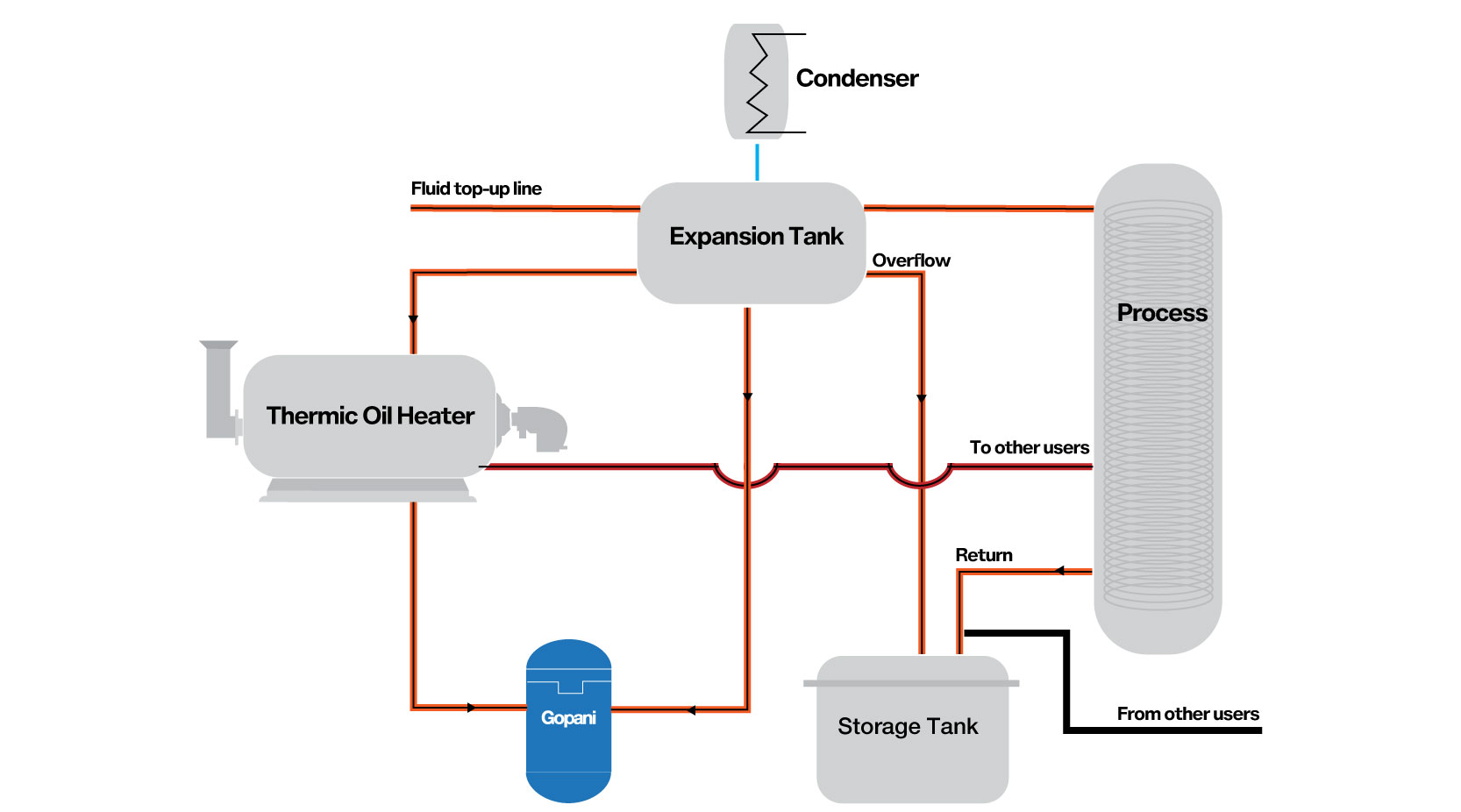

General Loop of HTF System:

As we saw earlier, the factors leading to risk and reduction in efficiency of the heat transfer fluids are mainly:

a) build-up of suspended solids, and

b) polymerized products.

The suspended solids can be due to pipe /vessel erosion, corrosion and/or carbon particles.

It is very important to continually filter the Heat transfer fluids and keep them healthy using the online filtration process. It is a smart way of filtering small flow of 5 m3/Hr from main loop and filter it back in the main system. Gopani products Systems has supplied such systems to several clients across the globe and has a proven track record of delivering excellent quality systems that have solved the contamination and particle build up issues in HTF processes.

Contact us to know more about our HTF filtration system

Gopani Product Systems

Putting Innovation in Filtration Since 1993

Who we are?

- ISO 9001:2015 Certified

- Quality Conscious

- Forward Thinking and People Positive

- Engineers and Innovators at Work

Resources

- What is Filter Cartridge?

- What is a String Wound Cartridge Filter?

- What is Melt Blown Filter Cartridge?

- What is a Pleated Cartridge Filter?

- Filtration and Separation

- Why Advanced Pre-filtration for Desalination?

- Advanced Filtration Solutions For Oil And Gas Industry

- Advanced Filtration Solutions For Chemicals & Solvents

- Advanced Filtration Solutions For Pharmaceuticals

- Process and Utilities Water Treatment

Our Trending Cartridge Filters Products

- Melt Blown Cartridge Filters

- String Wound Cartridge Filters

- Pleated Cartridge Filters

- ClaryFlow Big Buddy

- High Flow Filter Cartridges and Housings