Chapter 1: Basic Filtration

What are Filtration & Separation?

Filtration of fluids and separation of particles from fluids is critical to human life. Why? Because unless we remove particles from water or pollutants from the air, we do not get access to clean air and potable water.

A few decades ago, basic filtration technology was sufficient. However, today in addition to basic filtration for potable water and other fluids, extremely sterile air and water are also required for producing pharmaceuticals, APIs, cosmetics, and other such critical products. Hence incremental innovation in filtration and separation technology is has become essential. The absence of filtration or the inability to separate particles/contaminants/pollutants from fluids and gases changes everything. The quality of life dwindles and falls. Right from the grains we cook, the engines we run, to the power stations and manufacturing units, nothing will be the same without filtration.

As the world population grows, the world undergoes industrial growth and fights back pandemics like the COVID 19 – the need for filtration and better technology for filtration keeps growing.

Development Of Filtration Technologies Is Driven By:

- Need for Water

- Need for Food

- Need for Transportation

- Need for Environment Protection

- Need to Manufacture Goods

- Need for Sophisticated Healthcare

- And the Desire for a Higher Standard of Living

Industries use filtration to varying degrees based upon the purification and separation requirements. These industries include:

Water and Waste water:

- Drinking/potable water Purification

- Raw water Treatment

- DI water Treatment

- Process water Treatment

- Sewage water Treatment

- Waste water and Effluent Treatment

- Boiler Feedwater Treatment

- Water Reclaiming

Desalination:

- Remove Suspended Solids, Bacteria, SDI, Colour & Turbidity

- Oil removal from seawater

- Membrane prefiltration and protection

- Membrane biofouling protection

Pharmaceuticals and API Manufacturing:

- Depth Filtration for Precipitate Control

- Endotoxin and Bioburden Reduction

- Solids Removal Recovery and Reclaim

- Sterilizing grade Filtration

- Solvent & Bulk Chemical Filtration

- Utilities & Plant Services

Chemical:

- Cooling Tower Water Treatment

- Filtration of Corrosive Liquids and Harsh Chemicals

- Solvent Recovery

- Catalyst Recovery

- Recovery of Precious Metal from Spent Catalyst

- Filtration Processing with Viscous Mastics and Sealants

- Heat Transfer Fluid Filtration

Oil and Gas:

- Downstream Applications

- Injection water

- Produced water treatment

- Brine filtration

- Upstream Applications

- Combustion fluid filtration

- Catalyst filtration

- Condensate dewatering

- Rich amine treatment

- Lubricant oil filtration

- Food and Beverages

- Decolourisation of beverage

- Beverage polishing and taste enhancement

- Colloidal and microbiological stability for taste and longer shelf life of food and beverages

- 2 stage filtrations for Aroma enhancement and retaining rich flavours.

- Downstream Applications

melt blown cartridge filter 10 inch 1 micron, melt blown cartridge filter 10 inch 5 micron, melt blown cartridge filter india, melt blown cartridge filter

Principles of Filtration

Filtration happens on the principle that when two components in a mixture are more valuable separately or are more harmful when together, they need to be separated. There can also be scenarios where there are

a) contaminants in a high-value fluid

b) high-value solids present in a liquid.

Filtration must happen based on the value of the component that needs extraction. Here are some examples:

Remove Solids from Liquids:

A liquid/solution that is valuable might have solid particulates or harmful solid residue and contaminants. In this scenario, it is essential to remove solid waste from the solution. Some examples of such filtration include – pregnant liquor filtration or sugar solution filtration before it gets crystallized.

Remove Solids from Gas:

Many gases get released into the environment after use. Harmful contaminants, solids, and other particulates have to be removed from these gases before release. Some examples of such filtration include bottled gas filtration and filtration of kiln exhaust steam before release.

Remove Liquid from Solids:

Liquids are removed from solids to extract valuable solids for further processing and transport. For e.g. removal of liquid from metal ore for upstream operations. Here it might cause hazards if the system re-slurries and sloshes.

Recover Liquids and Solids:

When both liquid and solid are valuable, they are recovered separately. For example, in the fermentation process, the liquid contains valuable components like bioethanol and the solids are also a valuable component of animal feed. Another such example is catalyst recovery and precious metal recovery in chemical processes.

melt blown cartridge filter 10 inch 10 micron, melt blown cartridge filter 10 inch 20 micron, melt blown cartridge filter 10 inch 25 micron, melt blown cartridge filter 20 inch 1 micron

Filtration and Separation Mechanisms

Sedimentation or Gravity Settling: In this process, the heavier sediments settle down at the bottom. This method of separation is also known as cyclonic separation.

Straining or Sieving: Any particle larger than the pores of the medium gets held back. It does not pass through the medium. If the particles have higher inertia, they may break the medium and pass through.

Inertial Impaction: In this method, the particles do not follow the fluid stream. They continue on the existing path to intercept with the filter medium. This phenomenon, however, depends on the velocity of the fluid; and many other factors like temperature, density, viscosity, etc.

Interception: A particle that follows a streamline gets intercepted by a filter medium. Usually, in such cases, the flow is laminar. The likelihood of capturing the particle depends on pore size and particle size.

Electrostatic Deposition: In this method, the charge of particulate and the charge of the filter media are opposite. Hence when particulate comes near the filter media, it does not let it pass through and deflects the particle, depositing it back into the medium.

melt blown cartridge filter 20 inch 5 micron, melt blown cartridge filter 20 inch 10 micron, melt blown cartridge filter 20 inch 20 micron, melt blown cartridge filter 20 inch 25 micron

melt blown cartridge filter 30 inch 5 micron, melt blown cartridge filter 30 inch 10 micron, melt blown cartridge filter 30 inch 20 micron, melt blown cartridge filter 30 inch 25 micron

Filter Media

Choosing the right filter media is critical to achieving the desired filtration performance. Hence, achieve the desired quality of filtrate. A detailed understanding of filter media, its properties, and performance is the key to achieving desired output, and we will be covering the subject in this handbook. The topic is extensive, so let us start by understanding different types/forms of filter media:

Membrane, Film, or Plate:

There are a series of pores on plates, membranes, films, and other similar mediums to let the feed liquid pass through and stop the suspended particles at the surface. The possibilities are endless, from 10mm drilled pores on a steel plate to 1 billion+ pore per square centimetre in a polymer membrane.

The pores may not necessarily be drilled or punched. They may also get created due to the structure of the medium. For example, slots get made within a wire or ribbon spiral or in a stretched membrane.

Woven Fabric

The warp and weft weaving in a fabric creates pore-like gaps making them great filter mediums. Fabric is used as a filter medium to remove water from cottage cheese or hung curd in the kitchen for ages now. Fabric makes a filter medium in many industrial processes for filtration; however, it is not easy to specify an absolute rating as the warps and wefts of such filter medium can move under pressure causing different pore sizes across the surface.

Non-woven, Felt, or Spun.

Different types of fiber material, like polypropylene, nylon, glass fiber, polyester, metallic, ceramic, to name a few, intertwine to form a porous structure. The fibers used to construct a non-woven filter medium might be coarse, fine, smooth, long, short, thick, coarse, etc.

Particle Stack

A layer of particles/granules like salt, sand, gravel, or pebbles is stacked. These stacked particles form gaps between them, making this stack porous and equipped for filtration. The pores are small or large depending on the size and shape of the granules. Larger particles do coarse filtration, whereas a medium formed with finer particles makes a perfect fit for fine filtration.

Sintered

A sintered filter medium is made by putting particles under isostatic pressure and sintering them together to form a porous filter media. Typically sintering technology is used to engineer polymer or metallic filters. However, ceramic, glass, and other similar materials may also be sintered to form a porous filter media.

A combination of filter media or multiple layers of the same media may help achieve the desired filtration output.

Type of solid contaminants

- Viruses

- Bacteria

- Pigments

- Spores

- Aerosols

- Pollen

- Blast Furnace Dust

- Refractory Dust

- Zinc Oxide Dust

- Machining Dust

Some contaminants are visible to the naked eye, some seen via light scattering methods. Others are visible upon examination through a microscope or an electron microscope.

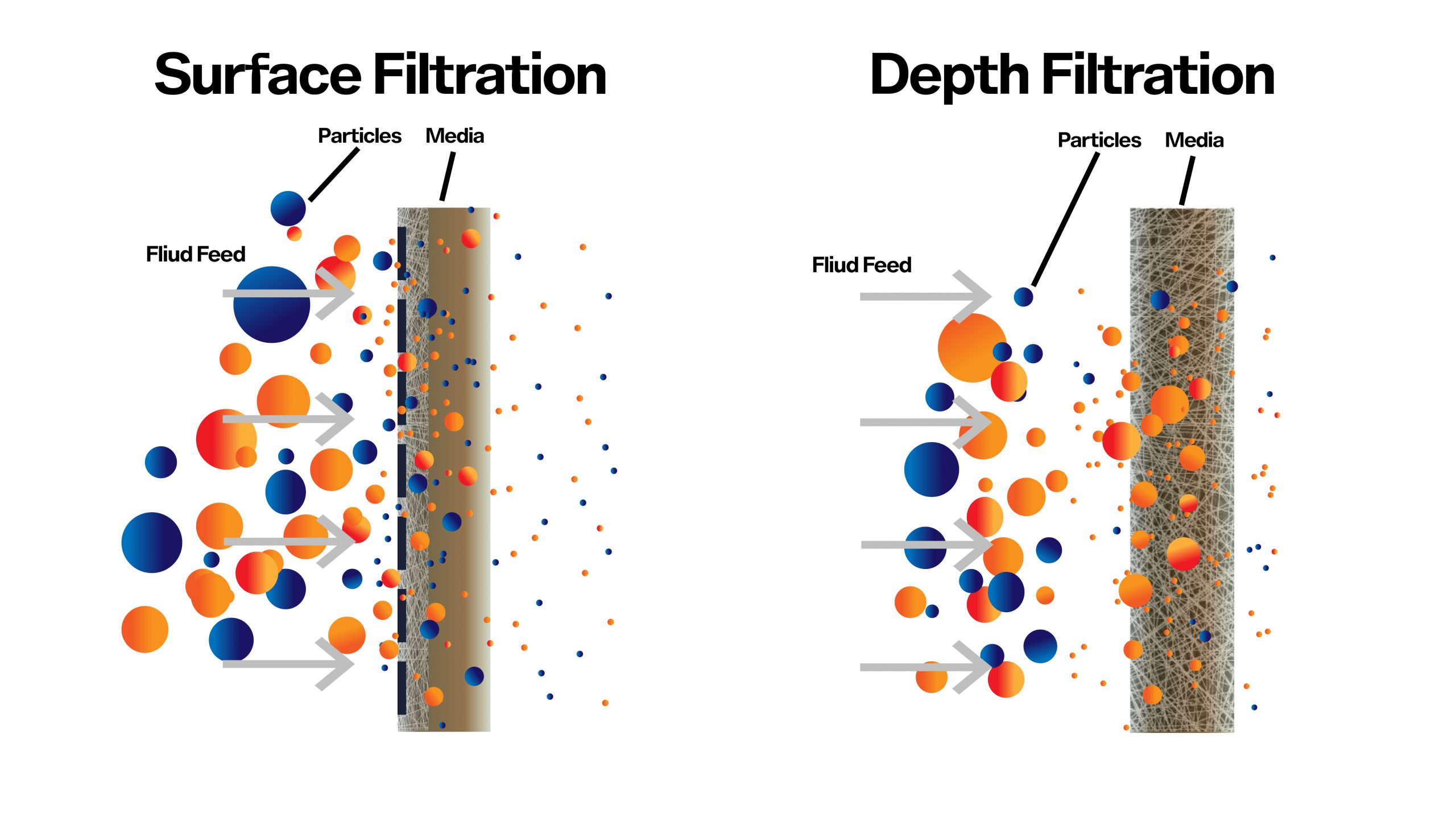

Surface, Cake, and Depth Filtration

If the particle size is larger than the pore size, it gets blocked at the surface. Sometimes pores are uniform; however, the particle size varies. In this case, larger particles remain at the surface, and smaller particles pass through easily. This process is an example of surface filtration. On the other hand, depth filtration captures particles at different levels. The filter medium does not have a uniform size of pores. Instead, pores are formed in a gradient from large to small. In this case, there are many opportunities to capture the particles as the fluid passes through the medium. The larger particles get blocked at the surface. The smaller particles are trapped inside the medium as they travel through the depths of the medium.

A cartridge is encased within a housing or a casing and used to remove unwanted particles, pollutants, and chemicals from liquids.

A cartridge is encased within a housing or a casing and used to remove unwanted particles, pollutants, and chemicals from liquids.

| Surface filters | Depth Filters | ||||

| Surface filters do not let the solids/contaminants enter through the medium. They restrict them outside the filter media. | Depth filters trap all the contaminants, pollutants and solids within the media. | ||||

| Surface filtration refers flow of fluid through to a layer of material that restricts particles on the surface | Depth filtration refers to a thicker layer of media/or multiple layers that sets a torturous path for the particles and restricts them from passing through. | ||||

| The cartridge filter size of particles restrained from entering the medium is higher than the mean pore size of the medium | The size of particles in much smaller than the mean pore size of the medium | ||||

| Over a period of time, the surface filter gets caked on the outside with particles and restricts the flow beyond acceptable limit. At this point the filtration surface has to be cleaned and reused. | Contaminants travel through the depth filter and get trapped there, gradually the pores in the filter get blocked and have to be cleaned using a reverse flow of fluid or replaced by a new medium. | ||||

| Surface filters are comparatively cheaper and have a shorter shelf life. | Compared to the surface filter, a depth filter is expensive but it has a longer shelf life. | ||||

| Mechanical strength of the filter medium is less (with the exception of filter medium made of stainless steel) | Mechanical strength of filter medium is high | ||||

| Example : Pleated cartridge filter, cellulose filter | Example: String wound filter, Ceramic filter and Sintered filters |

The media that does surface filtration may be cleaned and rejuvenated by backwashing. Backwashing refers to passing a stream of fluid in the opposite direction. This system can be automated or manual. It may also be possible to reclaim filters by dissolving the trapped particles by soaking the filter in hot water or another solvent.

Filters have a long or short service life depending upon the quality and construction of filter media. An alternative to reclaiming filters is a replacement. Filters also need to be replaced when they cannot be reclaimed. When the filtration output decreases or pressure across the filter increases, this is a sign that the filter must be replaced or processed for reclaiming.

melt blown cartridge filter 40 inch 5 micron, melt blown cartridge filter 40 inch 10 micron, melt blown cartridge filter 40 inch 20 micron, melt blown cartridge filter 40 inch 25 micron

Cake Preparation for Washing

It is often assumed that the drier the cake, the easier it is to wash. The reason why this is not true is that dry compressed cake becomes so compact that it does not let waste pass through. As a result, when it comes under pressure it develops cracks and may allow bypass. Hence it is only advisable to begin washing immediately after mother liquor is drained away. If too much time passes and the cake dries out completely it will develop cracks, will not be washed completely, will hamper filtration quality, and reduce the filter life.

Cake Washing Mechanisms

Displacement

Washing liquor is used to displace the mother liquor, it acts as a piston and drives the mother liquor out of the cake without any dilution. It is by far the most efficient method of cake washing under ideal conditions. However, the secret to achieving a high degree of plug flow effect it is important to prepare the cake well, and the careful application of washing liquor to the cake surface. The washing liquor has how viscosity compared to the mother liquor, and too much pressure can create cracks in the cake and easily pass between the cake cracks without actually washing the cake.

Cake washing in a way alters the cake structure and viscosity. It disturbs the cake’s physical structure and as a result, after a point, the washing liquid affects the cake, and the dilution process starts.

Dilution:

The filter cake is washed by dilution of the mother liquor through mixing with washing liquors. The purpose of washing the filter cake is to remove the unwanted substances from the cake and increase the purity of the quality of filtrationto recover desired substances.

However, if the mother liquor itself is the desired product, it should not be diluted with the wash liquid.

Cross-flow v/s dead-end filtration

In cross-flow filtration, the upstream flow runs across the filter medium. This cross-flow scours the filter cake that forms on the filter surface. Retentate from cross-flow filtration recovers residues with the feed liquid still present in them.

Dead-end Filtration

In dead-end filtration, the upstream flow runs towards the filter medium. This flow deposits solids on the filter medium or the filter cake. The dead-end filtration is used to recover dry solids.

Here is a diagram showing the profile of cross-flow and dead-end flow. The two cannot be directly comparable, however, they are chosen depending upon the needs of the process.

For a solid-liquid process to recover solids, a dead-end filtration is strongly recommended. In cases where a large part of fluid must be removed – cross-flow filtration is done – finally followed up with dead-end filtration to recover the solids.

Compressible Cake

It is a common assumption that when a filter cake forms, the particles are stacked closest together. However, in the real-world, cake density and height are different. Hence, the cake properties and permeability are different.

High pressure may form a highly compact cake with low permeability. Low pressure forms filter cakes with lower permeability.

Higher pressure does not necessarily mean better filtration. In fact, it can mean quite the opposite. Higher pressure creates a highly compact cake with lower permeability – hence decreasing filtration efficiency. As the cake grows, its permeability decreases, and the pressure across the filter medium drops.

Pre-coat and body feed

In some cases, the solids are either too fine or have a gel-like consistency. Hence it becomes difficult to achieve the desired filtration. In this scenario, a viable way to achieve fine filtration is by using porous material to form a bed of a three-dimensional array of pores. This three-dimensional array is created by

a) Pre-coating the filter medium

or

b) Adding the porous material into the feed liquid.

The filter aids are added to the feed body to bulk it up. They form a slurry that ensures a cake with higher permeability.

Filter Rating Parameters

Filters are tested and rated for their ability to remove particles of a specific size from fluids. There are many ways to determine and rate this ability of the filters via different tests and rating standards.

Real suspensions contain contaminants of different sizes, surfacetextures, and shapes. They have different chemical compositions and physical properties. In real-world applications, they are subject to high flows, different temperatures, pressure fluctuations, and much more.

Hence, in addition to the particle removal efficiency, filters are rated for the following factors.

Pressure Drop:

The liquid for filtration moves at a specific speed. The filter media obstructs the momentum of liquid causing the pressure to drop. Pressure drop is denoted as delta P or ∆P.

Chemical Compatibility:

Different chemicals have different PH values, chemical composition, acidity, and corrosive capabilities. Hence, one needs a compatible filter that will interact with the chemical without being adversely affected.

Strength:

A filter’s mechanical strength and ability to withstand harsh flows and other operating conditions is a critical parameter to consider. A filter with poor mechanical strength will buckle under high flows and high pressure.

Temperature Resistance:

Use a filter that can withstand the operating conditions at high efficiency even at the maximum temperature your operational environment reaches.

Viscosity:

Viscosityimpacts the speed at which a fluid passes through the filter. Viscous liquids have a higher pressure drop and can lead to shorter filter life.

In addition to all the above-mentioned factors, there are critical applications in food and beverage, API manufacturing, Pharma, and biopharma industries that require a certain safety standard, and sterile filtration requirements.

melt blown cartridge filter 50 inch 5 micron, melt blown cartridge filter 50 inch 10 micron, melt blown cartridge filter 50 inch 20 micron, melt blown cartridge filter 50 inch 25 micron

Filter Rating

Let us see a few popular rating mechanisms that help you choose the right filter for your application requirements.

Absolute rating:

A filter may not remove all the suspended solids. However, the filter has a particle size cut-off point. No particle above the size of this cut-off point should be able to pass through the filter medium. This cut-off point refers to the diameter of the particle, measured in micrometres or simply microns.

If the filter medium has an exact pore size, then this cut-off point is an absolute rating. However, most of the filter media do not have consistent pore sizes. Hence, filter mediums like felt, paper, and woven fabrics, are not “absolute rated”.

In real-world filtration conditions, the particles are not perfectly bead-shaped as assumed for an absolute rating. In rare cases where particles are needle-shaped, they may escape through pore size much smaller than the nominal size of the particle. As mentioned, such cases are rare because the filter medium is often layered or has a gradient-like depth. Hence, it is difficult for such particles to pass through. Additionally, filters often accumulate a thin layer of cake over the surface. This layer blocks particles, and filters become more efficient. They filter finer particles than their actual rating.

Your filter supplier may supply a filterwith a rating, maximum allowable flow, pressure, temperature, PH, etc. However, this is only for a general reference of whether the filter is compatible or not. Why? Because a non-compatible filter medium may puff up due to chemical absorption or close up due to excessive caking. If it cannot handle the force exerted by high flows, the filter media may distort and widen the pores at certain places. Thus, compromising the filtration quality.

Nominal Rating

Unlike the absolute rating, the nominal rating takes into consideration the percentage of particle retention. It represents the nominal efficiency of the filter as having 90%, 95%, or 98% retention capacity. For example, a filter of 10 microns with a 90% efficiency rating means that the filter can retain 90% of the contaminants of a size that can pass through pores of 30 microns.

However, plagued by a lack of uniformity and reproducibility, the test may give erroneous results. For example, a filter medium like felt, with a nominal rating of 30 microns, may pass particles anywhere between the size of 20% to 40% at the same time. It may also retain particles of much smaller size.

Mean Filter Rating:

A mean filter rating refers to the average pore size of a filter element. It makes more sense than the nominal rating as majority filter elements do not have a uniform pore size. The mean of different pore sizes across the filter medium establishes an average particle size above which the filter medium starts becoming effective.

Beta Ratio:

The beta ratio system gauges the ability of a filter to retain particles of a particular size. It also determines the amount or the concentration of contaminants in the fluid. The beta ratio refers to the number of particles of size A in the upstream fluid to particles of the same size in the downstream fluid. A higher beta ratio means higher capture efficiency. For example, beta ratio 1000 with 99.9% percent efficiency lets only 1000 particles of the 1,000,000 particles of a set size pass through the medium.

Microbial Rating:

In addition to removing the dirt and other contaminants, it is also essential to remove bioburden, bacteria, or fungus from the feed. This quality is especially desirable in critical applications for processing pharmaceuticals, APIs, and food and beverages. Typically, a filter that makes a liquid bacteria-free is suitable for sterilizing. A standard method to determine the microbial removal efficiency of the filter is to measure its log reduction value (LRV).

Filter permeability:

All filters are porous and allow a feed liquid to permeate through while blocking the unwanted contaminants. The permeability of the filters determines how much liquid is allowed to pass through at a set pressure drop. A filter with high permeability produces less reject liquid, while one with lower permeability rejects more liquid and converts only a small amount of the feed liquid into the filtrate. If the solid concentration in the feed liquid is high, the solids form a cake around the filter surface. Gradually as this cake builds up, the permeability of the filter medium decreases, and so does the output.

melt blown cartridge filter 10 inch 1 micron, melt blown cartridge filter 10 inch 5 micron, melt blown cartridge filter india, melt blown cartridge filter

Filter Tests

Filter testing labs put filters through several tests to gauge their performance and endurance and then provide a rating. There are various tests and methods to determine the efficiency of a filter and give a rating to the filter. These include:

Bead Challenge Test:

The bead challenge test determines the absolute rating of a filter and its efficiency. In this test, spherical glass beads or test material that closely resembles the size and property of real-life contaminants are added to the feed. These contaminants are added to the fluid in known concentration and passed through the filter media. The filtrate is examined for the beads and then rated for its absolute filtration efficiency. However, the data might be flawed as the contaminants present in real-world applications are not perfectly smooth and round.

Multi-Pass Test:

A multi-pass test determines the efficiency of filters in applications for hydraulic and lubrication systems. Here the fluid is circulated in a loop through a filter housing. Contaminants are continuously added to the feed to make up for the ones trapped by the filter. Standard test dust or ISO medium test dust makes up for the hydraulic and lubricating systems as the typical contaminants. Samples of the feed liquid and the filtrate are taken from the system at predetermined pressure drop levels.

This test simulates the behaviour of clarifying filters in hydraulic and lubrication systems.

Single-Pass Test:

Unlike the multi-pass test, a constant flow of suspension is fed into the filter. Here the filtrate is not recycled back into the filter. The filtrate is collected to measure the contaminants. The contaminants are allowed to accumulate on the filter with a simultaneous rise in differential pressure across the filter. Further, the feed and the filtrate are tested for particle count to determine the filter efficiency.

Bubble Point Test:

While most tests gauge the filtration output by measuring the difference between the feed and the filtrate, a bubble point test measures the characteristics of a filter and its pore size.

This test is based on the principle that when a porous filter medium is thoroughly wetted by immersion in a specific liquid, and when pressure is applied to force a gas bubble through the pore of this filter, then the amount of pressure is inversely proportional to the diameter of the pore.

In simple terms, it means that the pore size of the filter medium is determined by wetting the medium and measuring the pressure applied to force the gas bubble through the pore.

Dirt Capacity Test:

The single-pass test is a preliminary test that determines the ability of the filter medium to hold dirt within the medium. The dirt capacity test is a sophisticated method to find out the dirt holding capacity of the filter medium, resulting in pressure drop. Hence the service life of the filter. Contaminants are added to the upstream flow at regular intervals, and the differential pressure is recorded. The contaminants in the upstream liquid vs. the pressure drop are measured and plotted in a graph. In this way – maximum pressure drop and maximum solid accumulation capacity for a filter medium are determined. When the filter reaches this mark, it needs replacement.

Media Migration Test:

Media migration can be a pressing issue when non-compatible filters are used for critical applications. If the filter media is loose or has a surface that erodes easily, or if a filter is assembled using any kind of glue, binders, or sealants that will leach off into the filtrate, then the filters need immediate replacement. Hence a filter undergoes tests to ensure that the media does not leech or migrate into the filtrate and cause contamination.

Here the filter is tested by simulating different real-world application conditions including parameters such as fluctuating flow, flow reversal, mechanical vibration, to name a few.

Fatigue Tests:

The fatigue test submits the filter to multiple cycles where it undergoes fluctuating pressures, pulsating conditions, etc. before and after the fatigue test, the filter undergoes the bubble point test to affirm its integrity. Different filters have a different cycle life and can fail in 10000 cycles for steady flow cycles and 100,000 to 1,250,000 cycles for pulsating flow.

Glossary

Filtrate: Filtrate refers to liquid that has passed through the process of filtration.

Retentate: Retentate is the retained material. It is the portion of the feed solution that does not pass through a cross-flow membrane filter. It is retained by a filter or porous membrane

Permeate: The filtered fluid that is allowed to flow through a membrane.

Pores: Holes in a membrane filter that allow the desired fluid to pass through while blocking all other media.