Filtration drives the World!!

Thank God for filtration, today we have clean water to drink. Without filtration, the world wouldn’t be the same. Imagine a place where there is no clean drinking water. A world where an aircraft wouldn’t fly, cars wouldn’t be seen on roads, and ships wouldn’t sail. Food and pharma products would not aid good health and would instead lead to illnesses, and we would be breathing in a very dangerous environment. There would be mass scale malnutrition among children and societies would suffer.

Without filtration and separation, the world would be less clean, less sustainable, highly expensive, and less livable.

Everything around us, the air we breathe, the water we drink, the cars that we drive, the houses we build, and the food we eat is produced using filtration to varying degrees. Essentially, every liquid which is a direct product or is used to manufacture another product has to go through filtration.

Development of filtration technologies is driven by:

- Need for water

- Need for food

- Need for transportation

- Need for environment protection

- Need to Manufacture goods

- And the desire for a higher standard of living

What is filtration?

Filtration can be defined as: A physical/mechanical process of selective removal of particles from any given solids, liquids, or gases by passing them through a chosen medium.

Two most important branches of filtration are:

Removal of solids from liquids

Example:

Remove sediments from drinking water, particles from breathable air, particles from a fuel that is used to power vehicles, or removal of metallic and non-metallic particles from lubricants or from compressed air or processed water.

Control emissions from basic industrial processes to prevent fouling from happening downstream.

Recovery of valuable products from solid, liquid or gaseous waste

Example:

Separation processes like desalination of seawater, membrane separation, etc.

Physical Principles of Solid – Liquid Filtration

The goal of filtration is to separate two components that may be either less valuable, or harmful when they are together. The physical principles applied for this process include:

Recovery of valuable solids from liquids

A liquid substance might be valuable and solid substance be the contaminant or a harmful residue. For example: Mined metal ore extraction by removing water first by physical means and then via thermal evaporation

Recovery of valuable liquids by filtering out the solid waste

A solid waste might be contaminating the liquid and need to be removed in order to make the liquid more valuable. For example: removal of sediments from drinking water.

Recover both solids and liquids

A fermentation process is used to separate the solids and liquids when both are of high value individually. For example: separation of bioethanol and solid components used as animal feed.

Physical Principles of Gaseous Filtration

When water passes through the filter it is known as filtrate, however in gaseous substances, the filtered substance is often known as cleaned air or gas.

- It is more common to remove solids and recover gas/air as a valuable product.

- However uncommon, it is not unknown to recover valuable solids from gas Example: paint recovery

There are various Filtration techniques used to seperate solids from liquids, liquids from solids, solids from gases etc. Let us see how the filtration and separation spectrum looks like and what different techniques are used across this spectrum.

The filtration and separation spectrum!

| Mixed phases | |

| Vaporization | Distillation |

| Evaporation and drying | |

| Sublimation | |

| Condensation | |

| Sorption | Absorption |

| Adsorption | |

| Phase transfer | Diffusion |

| Leaching and Extraction | |

| Distinct phases | |

| Solid from solid | Screening and Elutriation |

| Classification | |

| Solid from Fluid | Filtration |

| Sedimentation | |

| Flotation | |

| Scrubbing (wet or dry) | |

| Electrostatic precipitation | |

| Liquid from liquid | Sedimentation |

| Coalescing | |

| Liquid from Gas | Demisting |

| Sedimentation | |

| Gas from liquid | Defoaming |

| Sedimentation |

Filtration MicronRating

There is a general misconception in the industry and even amongst some learned engineers, that filtration rating is all about the micron rating or the ability of the filter to remove solids of a specific size from a liquid or gas. However, we have seen that filtration does not refer to a standard method. There are many filtration techniques, and each of them serves a different need. Hence there cannot be a single scale to rate them all.

Each industry has its own understanding of filtration and filtration quality standards (also influenced by regional/country-specific laws) that keep evolving. To understand and summarize filtration efficiency, a study of the following ratings may be interesting:

- Microbial rating

- Beta ratio

- Nominal filtration rating

- Absolute filtration rating

- Filter permeability

Quality assurance at Gopani – ISO 9001:2015 certified

At Gopani, we test our filtration systems using the bead challenge test in single and multi-pass tests, bubble point test analysis, filterability tests, laser particle analysis, media migration tests, etc. We ensure that our filters perform better than the best filters in the industry. Testing our filters against an array of parameters not only helps us develop better products but also provide support to customers to understand and optimize their processes.

Our Resources

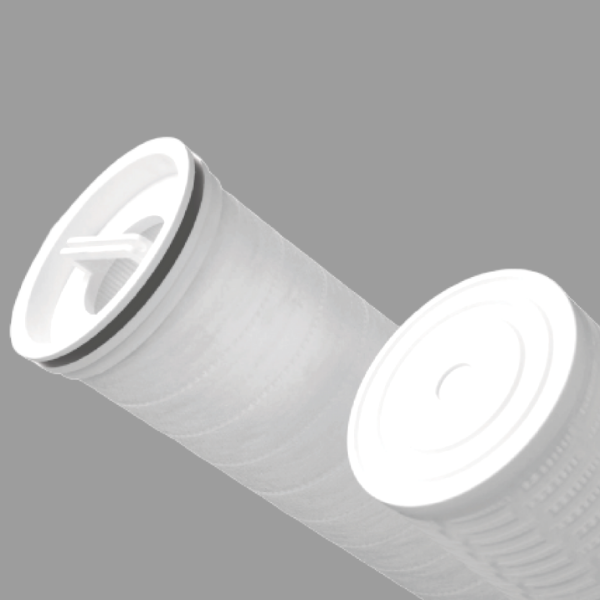

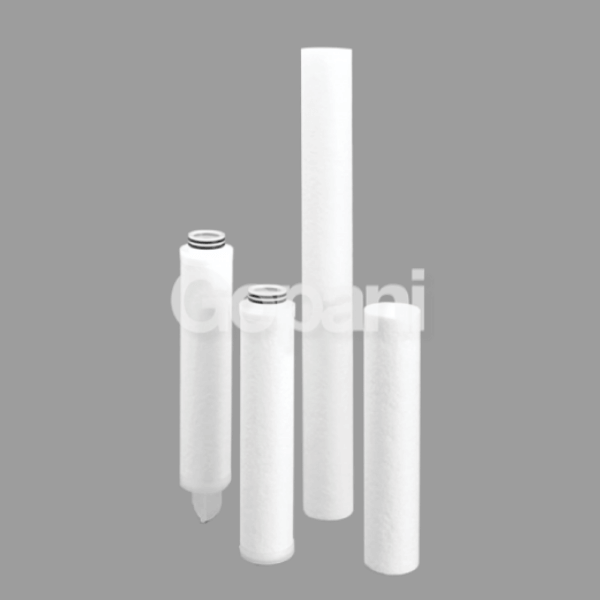

- What is Filter Cartridge?

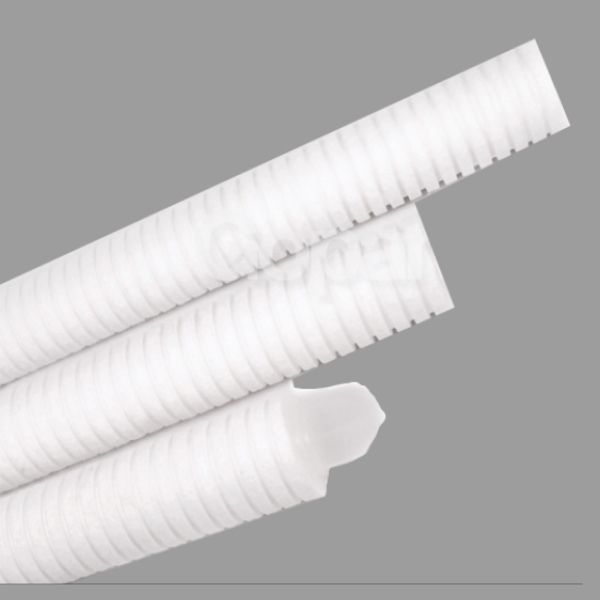

- What is a String Wound Cartridge Filter?

- What is Melt Blown Filter Cartridge?

- What is a Pleated Cartridge Filter?

- Filtration and Separation

- Why Advanced Pre-filtration for Desalination?

- Advanced Filtration Solutions For Oil And Gas Industry

- Advanced Filtration Solutions For Chemicals & Solvents

- Advanced Filtration Solutions For Pharmaceuticals

- Process and Utilities Water Treatment

Choose your Filtration System

Choose your Filtration Consumable